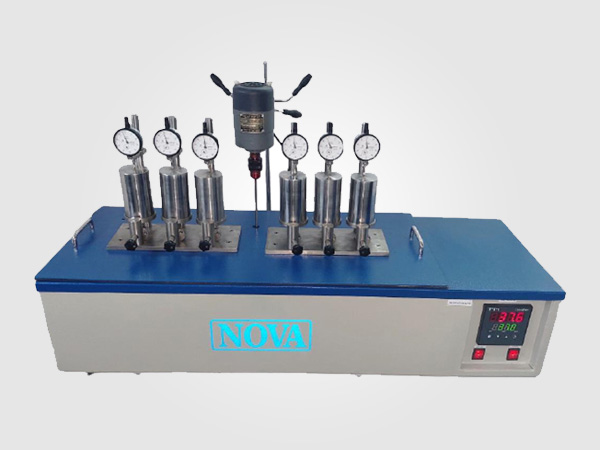

Indentation bath is to measure the indentation hardness of polymeric coated pipes as per prescribed temperature & weight mentioned in Standards. The different volume size models are available that can test 3/6/12 samples as per the requirements at different temperature range. All components in contact with fluid are made from Stainless Steel grade 304. Analog gauge OR Digital gauge OR Displacement Sensor can be configure as per requirement. This system is also available with HMI model which will record test parameters at settable interval for the entire test duration, can display recorded data as a graph on screen.

ISO 21809-1/DIN 30670 standards: Flap tip indenter 1.8mm Diameter, Weight 250gm & Load 2250gm.

| Features / Model | Model 1 (Hot) | Model 2 (Cool) |

| Number of Testing Stations | 3/6/12 | 3/6/12 |

| Temperature range | +5°c above ambient to +80°c/130°c | Ambient to +23°c |

| Temperature Accuracy | ±2°c or better | ±2°c or better |

| Media | Water / Silicon Oil | Water |

| Display | Analog (Digital gauge Optional) |

Analog Dial Gauge (Digital gauge Optional) |

| Data Recording | In HMI model (Optional) | In HMI model (Optional) |

| Temperature Control | Automatic Control Panel (PID) | Automatic Control Panel (PID) |

| Timer | Timer: 1 to 9999 mins (0.01 to 166 Hours) |

Timer: 1 to 9999 mins (0.01 to 166 Hours) |

| Dial Gauge | 0 to 10mm L.C. 0.01mm | 0 to 10mm L.C. 0.01mm |

| Construction Inner body | SS 304 | SS 304 |

| Construction Outer Body | SS powder coated | SS powder coated |

| External Refrigerated Bath | Not Required | Required |

| Two Step load | ||

| All Dial Gauges, Temperature Controllers,weights (Load)shall be calibrated with NABL Traceability Note: Media Silicon Oil not within our scope of supply. |

||

Indentation bath is to measure the indentation hardness of polymeric coated material/sampleas per prescribed temperature & weight mentioned in Standards. The different volume size models are available that can test 3/6/12 samples as per the requirements at different temperature range. All components in contact with fluid are made from Stainless Steel grade 304. Outer chamber made of M. S. duly powder coated.

Applicable Standard: ISO 21809-1/DIN 30670 standards.

| Features / Model | Model 1 (Hot) | Model 2 (Cool) |

| Number of Testing Stations | 3/6/12 | 3/6/12 |

| Temperature range | +5°c above ambient to +80°c/130°c | Ambient to +23°c |

| Display | Analog Dial Gauge (Digital gauge Optional) |

Analog Dial Gauge (Digital gauge Optional) |

| Temperature Control | Automatic Control Panel (PID) | Automatic Control Panel (PID) |

| Timer | Timer: 1 to 9999 mins (0.01 to 166 Hours) |

Timer: 1 to 9999 mins (0.01 to 166 Hours) |

| Dial Gauge | 0 to 10mm L.C. 0.01mm | 0 to 10mm L.C. 0.01mm |

| External Refrigerated Circulated Bath | Not Required | Required |

| All Dial Gauges, Temperature Controllers,weights (Load)shall be calibrated with NABL Traceability Note: Media Silicon Oil not within our scope of supply. |

||